New Research Shows Graphene Coating Can Protect Against Corrosion

Researchers at the Institute for Basic Science (IBS) have recently demonstrated that a graphene coating can protect glass from corrosion.

According to the researchers, their published study, found in the American Chemical Society’s, can solve problems related to glass corrosion in several industries.

Glass has a high degree of both corrosion and chemical resistance. For this end, it is the primary packaging material to preserve drugs and chemicals, the researchers note.

However, when shown over time at high humidity and pH, some glass types can corrode. Corroded glass loses its transparency, and its force is also reduced. As a result, the corrosion of silicate glass, the most common and oldest form of glass, by water is a serious problem, the researchers say—especially for the pharmaceutical, environmental, and optical industries, and particularly those in hot and humid climates.

Although there are varying types of glass, the researchers explain that ordinary glazing and containers are usually made of silicon dioxide (SiO2) and sodium oxide (Na2O), along with secondary additives. Glass corrosion begins with the adsorption of water on the glass surface. Hydrogen ions from water then distribute into the glass and exchange with the sodium ions present on the glass surface. The pH of the water near the glass surface increases, allowing the silicate structure to dissolve.

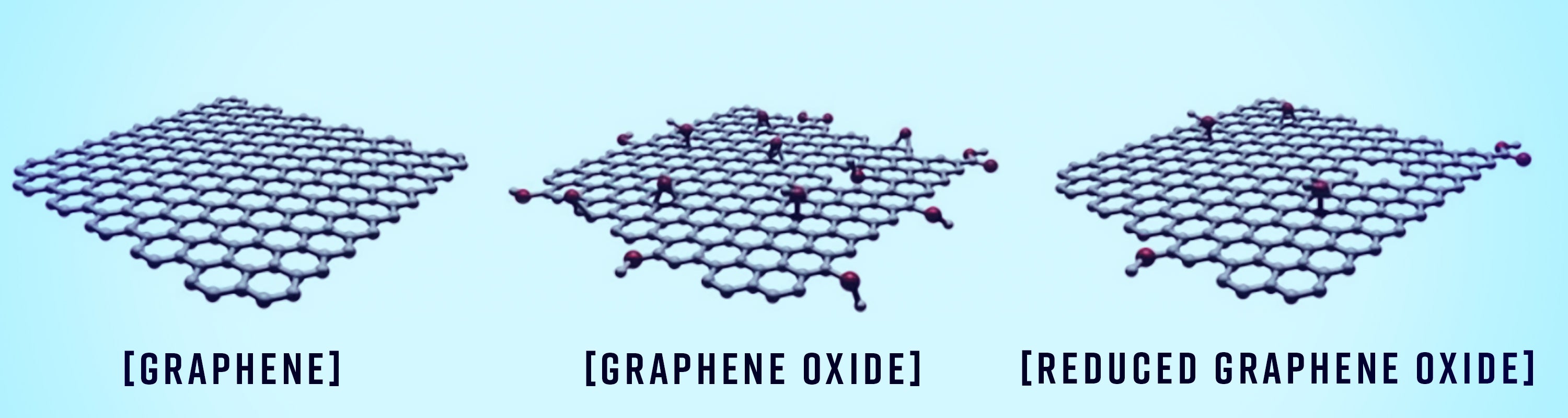

Scientists have examined how to coat glass better to protect it from damage. According to the researchers, an ideal protective coating should be thin, transparent, and provide a good diffusion barrier to chemical attack. Graphene possesses chemical inertness, thinness, and high transparency, making it very promising as a coating material.

Moreover, owing to its excellent chemical barrier properties, a graphene coating can block helium atoms from infiltrating through it. The use of graphene coating is also being examined as a protective layer for other materials requiring resistance to corrosion, oxidation, friction, bacterial infection, electromagnetic radiation, and more.

IBS scientists grew the graphene on copper and transferred either one or two atom-thick layers of graphene to both sides of rectangular pieces of glass. The effectiveness of the graphene coating was evaluated by water immersion testing and observing the differences between uncoated and coated glass.

After 120 days of immersion in water at 60 °C, the uncoated glass samples had significantly increased surface roughness and defects while reducing fracture strength. In contrast, both the single and double-layer graphene-coated glasses had virtually no change in fracture strength and surface roughness.

“The purpose of the study was to determine whether graphene grown by chemical vapor displacement on copper foils, a now established method, could be transferred onto glass, and preserve the glass from corrosion,” says Prof. Rodney S. Ruoff, director of the CMCM and a professor at the Ulsan National Institute of Science and Technology (UNIST).

“Our study shows that even one-atom-thick layer of graphene does the trick,” he adds. “In the future, when it is possible to create larger and yet higher-quality graphene sheets and to optimize the shift on glass, it seems reasonably likely that graphene coating on the glass will be used on an industrial scale.”

Read more